Discover why major retailers rely on the Higg Index to benchmark and index their sustainability efforts. […]

Quality Management

11 Common Mistakes When Building Audit Checklists in Excel

Audit checklists are indispensable tools for ensuring compliance and identifying risks across various industries, but designing them in Excel often introduces inefficiencies and errors. This blog post explores 11 common mistakes made when building audit checklists in Excel and offers actionable solutions, including how Certainty Software’s tools streamline the process and eliminate these pitfalls. […]

Quality Assurance vs. Quality Control

Quality Assurance and Quality Control are often used interchangeably, but their distinct roles in quality management are critical for manufacturing success. Discover how QA prevents defects while QC ensures final product quality, and why integrating both processes drives operational excellence. […]

[Podcast] Compliance Talks Episode 1: The Cost of Enterprise Non-Compliance (How Automation Prevents These Steep Costs)

In this debut episode of Compliance Talks, we dig into the true cost of non-compliance—financial penalties, operational disruptions, and reputational damage—and explore how Certainty Software’s automation is changing the way enterprises tackle these challenges. […]

Guide to Pre-Shipment Inspections

Pre-shipment inspections (PSI) are essential for ensuring product quality, compliance, and customer satisfaction in the global marketplace. Discover more about pre-shipment inspections here.

[…]

How Risk-Based Thinking Aligns with ISO 9001:2015 Requirements and Other Global Quality Assurance Regulations

Discover how Risk-Based Thinking (RBT) aligns with ISO 9001:2015 and other global quality assurance standards. Learn about the benefits of RBT, its integration into quality management systems, and emerging trends that are shaping the future of quality assurance. […]

Audit vs. Inspection: Learn Their Key Differences

Explore the crucial differences between audits and inspections in our latest post. Understand how each plays a distinct role in enhancing management system integrity, from strategic audits that align with broad objectives to detailed inspections focused on immediate compliance and safety. […]

How to Make an Audit and Inspection Checklist in Microsoft Excel

Businesses that perform regular internal audits and inspections often rely on checklists to cover their processes. Using Excel for checklists can streamline the data collection process, resulting in easy-to-follow lists that save time and maintain accuracy. This step-by-step guide will help you create audit checklists in Excel from scratch. […]

EU Passes Nature Restoration Law: A Milestone for Biodiversity and Climate Action

The European Union has made history by passing a landmark law to restore and protect nature across its land and sea areas. The Nature Restoration Law, which was approved by the European Parliament on February 27, 2024, is the first continent-wide, comprehensive law of its kind. It is a key element of the EU Biodiversity Strategy, which aims to halt and reverse the loss of biodiversity and ecosystem services by 2030. […]

A Comprehensive Guide to Root Cause Analysis

Root Cause Analysis (RCA) is a systematic and rigorous process that helps you to find and solve the underlying causes of problems in your organization. In this comprehensive guide, you will learn what RCA is, why it matters, and how to perform it in five easy steps. […]

Inspection Management Software Solutions: Build or Buy?

To guarantee quality, safety, and compliance in a variety of sectors, inspection management software is an essential tool. It assists with automating processes, managing corrective actions, data collection, report generation, and workflow streamlining. However, many enterprises struggle with which direction is better: purchasing a pre-built solution from a vendor or creating your own unique one. To help you choose the best solution for your needs, we will weigh the advantages and disadvantages of each option in this blog post. […]

4 Tips to Preventing Non-Conformances

Non-conformances are deviations from established standards, procedures, or specifications that can affect the quality, safety, or compliance of your business. In this blog post, you will learn the different types of non-conformances, how to prevent them effectively, and how Certainty Software can help you streamline your quality management system. […]

Corrective Action Examples: 5 Scenarios and Solutions

In this blog article, we will examine a few hypothetical scenarios that show the necessity of taking corrective action in several business areas. We’ll also talk about potential tactics and methods that could be used to stop or lessen the consequences of these hypothetical outcomes. […]

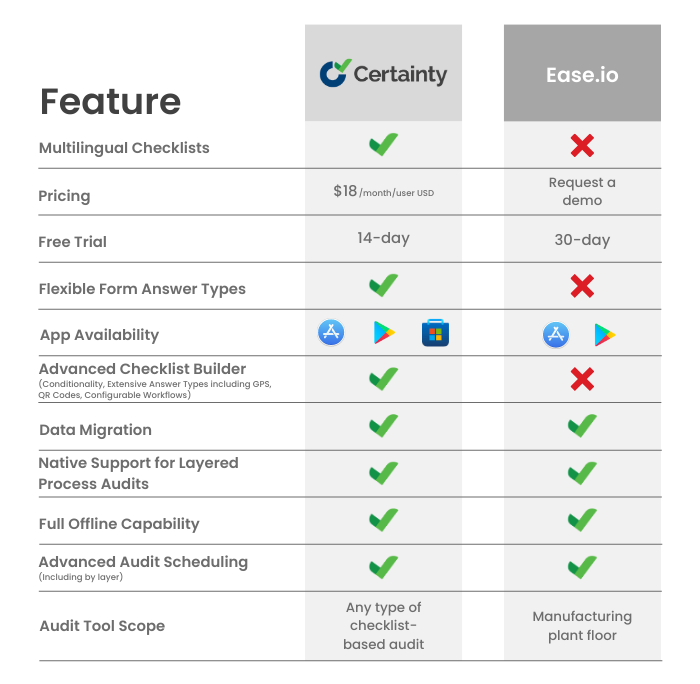

Ease.io vs. Certainty Software: Which Audit and Inspection Management Software is Right for You?

Overview If you are in charge of carrying out audits and inspections for your company, you are aware of how crucial it is to have dependable and effective software to handle your procedures. We at Certainty Software are aware that you want a tool that enables you to make and distribute checklists, gather and analyze […]

What is a BRC Audit and How to Perform One

BRC audits are independent assessments that verify your business’s compliance with a specific BRC standard. They help you improve your quality, safety, and compliance. This guide covers everything from preparation to reporting and follow-up. […]