Table of contents

Supply chain management is a critical function for any organization that produces or delivers goods and services. A well-managed supply chain can enhance functionality, sustainability, and profitability. Even little changes to improve supply chain management have shown to make a difference. For example, reducing supply chain costs from 9% to 4% can double your profits. while a poorly managed one can lead to disruptions, inefficiencies, and losses.

A supply chain audit is a systematic and comprehensive evaluation of your supply chain processes, from procurement to delivery. The purpose of a supply chain audit is to identify and eliminate potential risks, ensure compliance with regulatory and customer requirements, and drive continuous improvement initiatives.

In this ultimate guide, we will walk you through the key steps and best practices for conducting a successful supply chain audit. We will also provide you with some useful tips and tools to help you optimize your supply chain performance and gain a competitive advantage in your market.

Understanding the Scope and Objectives of a Supply Chain Audit

Before you start your supply chain audit, you need to define the scope and objectives of your assessment. The scope of your audit will depend on the size, complexity, and nature of your supply chain, as well as the specific issues or areas that you want to focus on.

Some of the common components and areas that you may want to include in your supply chain audit are:

- Procurement: The sourcing, purchasing, and contracting of raw materials, components, and services from external providers.

- Inventory management: The storage, handling, and tracking of materials and products throughout the supply chain.

- Manufacturing process: The transformation of raw materials into finished goods, using various methods and technologies.

- Logistics: The transportation, distribution, and delivery of goods and services to customers.

- Quality control: The inspection, testing, and validation of products and processes to ensure they meet quality standards and specifications.

- Supplier relationships: The communication, collaboration, and evaluation of suppliers and their performance.

- Cybersecurity: The protection of data, systems, and networks from unauthorized access, theft, or damage.

- Sustainability: The environmental, social, and economic impact of your supply chain activities.

The objectives of your supply chain audit will depend on your unique organizational goals, strategies, and challenges. Some of the common general objectives of a supply chain audit are:

- Identifying inefficiencies, bottlenecks, and waste in your supply chain processes and workflow.

- Mitigating risks such as disruptions, delays, errors, fraud, or breaches in your supply chain operations.

- Ensuring compliance with legal, regulatory such as the German Supply Chain Act, ethical, and customer requirements in your supply chain practices.

- Driving continuous improvement in your supply chain performance, productivity, and profitability.

- Enhancing customer satisfaction and loyalty by delivering high-quality products and services on time and at a competitive price.

Preparing for a Supply Chain Audit

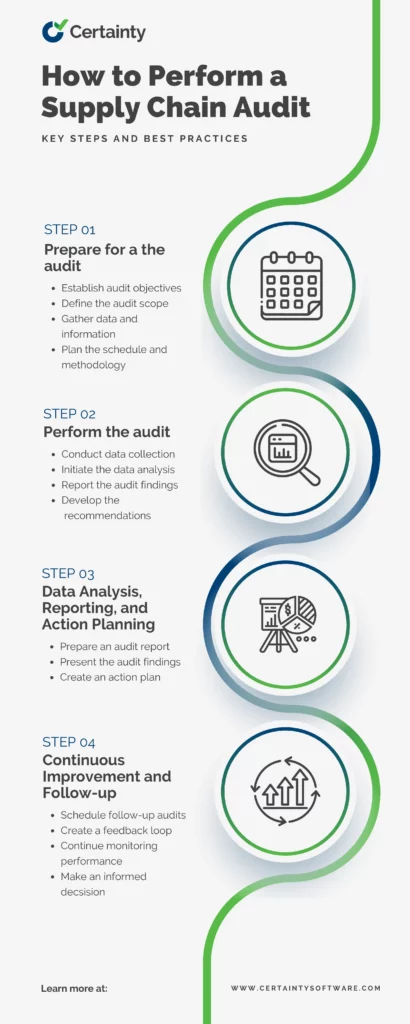

Once you have defined the scope and objectives of your supply chain audit, you need to prepare for the actual execution of the assessment. Here are some steps that you need to follow to prepare for a successful supply chain audit:

1. Establish audit objectives

Based on your scope definition, you should specify what you want to achieve from your audit. For example, you may want to assess the effectiveness of your inventory management system or evaluate the cybersecurity posture of your suppliers. You should also define the criteria or standards that you will use to measure your audit results.

2. Define the audit scope

To effectively conduct your audit, it is necessary to identify the specific aspects or segments of your supply chain that require attention. This may involve focusing on a particular product line or geographic location. Additionally, it’s important to determine the time frame for data collection and analysis during the audit process.

3. Assemble an audit team

After determining your audit scope and objectives, select the appropriate people who will conduct the audit. It may be beneficial to include internal auditors from different functions or departments or external auditors from third-party firms or agencies. Consider also assigning roles and responsibilities to each team member.

4. Gather necessary documentation and data

Next, collect the relevant information and evidence that will support your audit findings and recommendations. This may include documents such as contracts, invoices, receipts, reports, policies, procedures, manuals, or records. You may also need to gather data from various sources such as databases, systems, apps, sensors, or IoT devices. Also, ensure that your documentation and data are accurate, complete, and up-to-date.

5. Plan the audit schedule and methodology

The final step in preparing for your supply chain audit is to plan the timing and approach of your audit activities. This may require coordinating with your suppliers, customers, or other stakeholders to arrange site visits, interviews, or observations. You should also decide on the methods and tools that you will use to conduct your audits, such as checklists, questionnaires, surveys, or software.

If you are looking for a detailed and ready-to-use checklist template to quickly get started on your supply chain audits, Certainty offers a free-to-download Supplier Social and Environmental Compliance Checklist and German Supply Chain Act (GSCA) Due Diligence Checklist.

30+ Audit and inspection checklists free for download.

Conducting the Supply Chain Audit

Now that you’ve successfully prepared for the supply chain audit, you’re ready to execute the actual assessment of your supply chain processes and performance. Here are some steps that you should follow to conduct a successful supply chain audit:

1. Perform data collection

Gather the necessary information and evidence from your supply chain sources. You may use various techniques such as document review, data analysis, site visits, interviews, or observations. You should ensure that the data collection is objective, consistent, and comprehensive.

2. Conduct data analysis

Next, analyze the data that you have collected from your supply chain sources. You may use various techniques such as benchmarking, gap analysis, root cause analysis, or SWOT analysis. You should ensure that the data analysis is reliable, valid, and relevant.

3. Report your audit findings

With your data now analyzed and adequate information has been gathered, you can now identify and report the strengths and weaknesses of your supply chain processes and performance. Here you should also highlight the risks and opportunities that you have discovered in your supply chain operations. It’s vital to ensure that the audit findings are clear, concise, and supported by evidence.

4. Develop recommendations

To wrap up the stage of performing the supply chain audit, you should provide suggestions and guidance for improving your supply chain processes and performance. You may need to also propose corrective actions and preventive measures for addressing the risks and issues that you have identified in your supply chain operations. Your audit recommendations need to be realistic, feasible, and aligned with your organizational goals.

Data Analysis, Reporting, and Action Planning

After you have conducted your supply chain audit, you’ll need to communicate and implement the results of your assessment. Here are some steps that you need to follow to complete a successful supply chain audit:

1. Prepare an audit report

Based on your audit findings and recommendations, prepare a formal document that summarizes the results and outcomes of your supply chain audit. Your audit report should include a brief introduction, an executive summary, a detailed description of your audit scope, objectives, methodology, findings, recommendations, and a conclusion. Also, attach any relevant documentation or data that supports your audit report. It’s best practice to ensure that your audit report is accurate, complete, and professional.

2. Present the audit findings

Now with a completed audit report, you can present and discuss the results and outcomes of your supply chain audit with your stakeholders. Your stakeholders may include senior management, supply chain professionals, risk managers, or external parties such as suppliers or customers. The audit presentation should highlight the key points and insights from your audit report, as well as the expected benefits and impacts of implementing your audit recommendations. Another best practice is to solicit feedback and input from your stakeholders on your audit report and recommendations and ensure that your audit presentation is clear, concise, and engaging.

3. Create an action plan

Based on your audit report and presentation, you need to develop and execute a plan for implementing your audit recommendations. Your action plan should include a list of specific actions, responsibilities, timelines, resources, and metrics for each of your audit recommendations. You should also assign roles and accountabilities to the people who will be involved in carrying out the action plan. You should ensure that your action plan is realistic, measurable, and achievable.

Continuous Improvement and Follow-up

After you have completed your supply chain audit, you need to monitor and evaluate the progress and performance of your action plan. Here are some steps that you need to follow to ensure continuous improvement in your supply chain operations:

1. Regularly schedule follow-up audits

With your action plan built, it’s best practice to conduct regular follow-up audits to check the status and effectiveness of your audit recommendations. You may use similar techniques and tools as in your initial supply chain audit, such as document review, data analysis, site visits, interviews, or observations. It’s important to ensure that the follow-up audits are timely, consistent, and comprehensive.

2. Create a feedback loop

Based on your follow-up audits, collect and analyze feedback from your stakeholders on the implementation and impact of your audit recommendations. Techniques and tools that are effective at this stage include surveys, interviews, or focus groups. When collecting feedback, it’s important that you collect honest, constructive, and relevant feedback.

3. Continue to monitor your performance

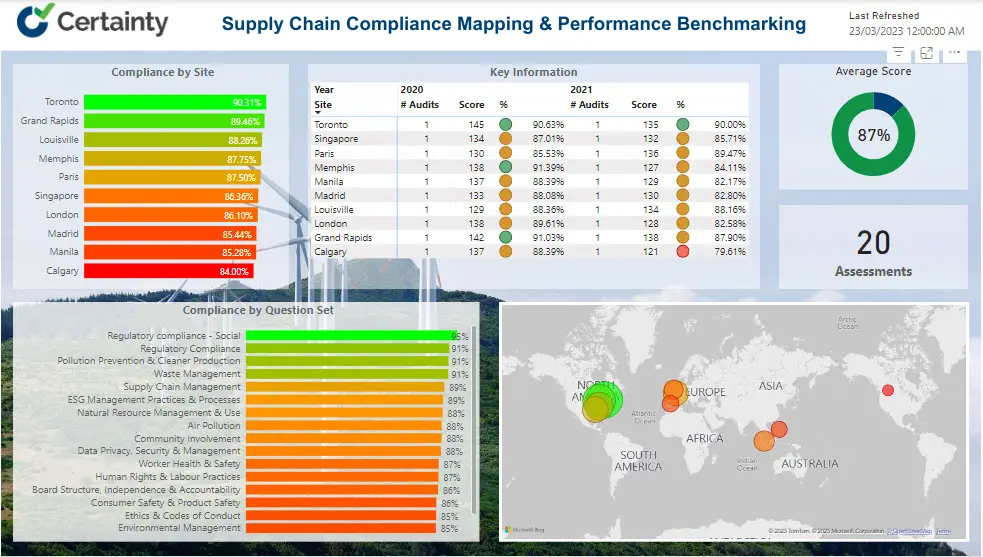

With your collected feedback, it’s up to you to measure and track the outcomes and benefits of your audit recommendations. You may use various metrics and indicators such as cost savings, quality improvement, customer satisfaction, or risk reduction. Make sure that the performance monitoring is objective, reliable, and valid.

4. Make an informed decision

Finally, using your performance monitoring, make informed and data-driven decisions for improving your supply chain operations. Techniques and tools that assist at this stage of the supply chain audit process could be dashboards, reports, or charts. For best practice, your decision-making should be strategic, proactive, and aligned with your organizational goals.

Conclusion

A supply chain audit is a valuable tool for enhancing your supply chain functionality, sustainability, and profitability. By following the key steps and best practices outlined in this ultimate guide, you can conduct a successful supply chain audit that will help you identify and eliminate potential risks, ensure compliance with regulatory and customer requirements, and drive continuous improvement initiatives.

If you need help with conducting a supply chain audit or implementing a supply chain management system, Certainty can assist you. As a provider of software solutions for auditing, inspecting, and validating your supply chain processes and performance, you can easily plan, conduct, report, and follow up on your supply chain audits using customizable checklists, workflows, and analytics.

If you’d like to learn more about how Certainty can assist with your specific audit and inspection needs, book a quick call and we’ll be happy to help.

You might also be interested in: