The thorough skill of Hazard and Operability (HAZOP) analysis serves as a sentinel against potential calamities in the field of process safety. HAZOP analysis functions as both a safety watchdog and a driver for operational improvement by dissecting industrial processes and evaluating every operational component. We explore the complexities of HAZOP in this detailed guide, revealing its systematic methodology, crucial benefits, and pivotal role in fostering a culture of safety and efficiency. […]

Safety Management

Manual or Automated Safety Audits: Which is Better?

The main distinctions between manual and automated safety evaluations are explored in this blog article as we set off on a voyage of exploration. We’ll examine the effects of these tactics on various workplace safety management practices, highlighting their advantages and potential drawbacks. […]

Certificate of Conformity: The Ultimate Guide for Manufacturing Companies

A Certificate of Conformity (CoC) is a document that certifies that your product meets the required standards or specifications. It can help you ensure product quality and safety, avoid legal liabilities and penalties, and enhance customer confidence and brand reputation. In this ultimate guide, we will explain everything you need to know about CoC for manufacturing companies. […]

What is a Cold Work Permit and How to Use It Effectively

Do you work in an industry that involves hazardous activities or environments? If so, you need to know what a cold work permit is and how to use it effectively. In this blog post, we will explain everything you need to know about cold work permits and how Certainty Software can help you with your safety needs. […]

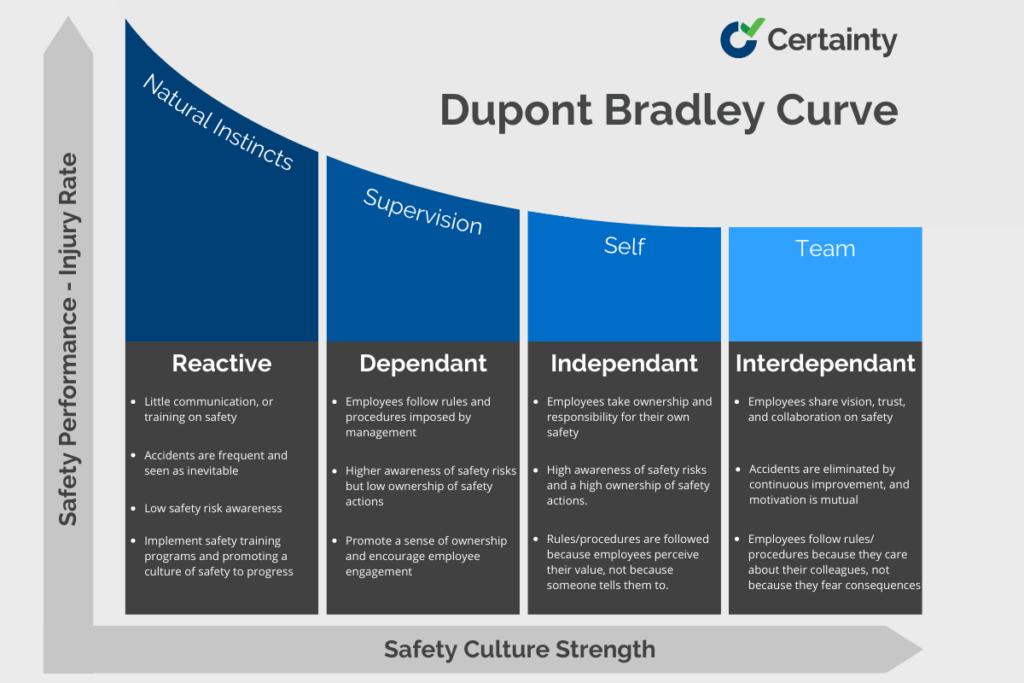

Improving Occupational Safety With the Bradley Curve

The Bradley Curve is a framework that illustrates the relationship between safety culture and operational performance. It shows how improving safety culture leads to better outcomes in other aspects of performance, such as quality, efficiency, and profitability. In this blog post, we will delve into the fundamentals of the Bradley Curve, exploring its significance, applications, and how it can help businesses streamline their operations. […]

Fire Extinguisher Inspection: The Ultimate Guide for the Workplace

Fire extinguisher inspections are crucial for maintaining workplace safety and compliance with fire codes and standards. They involve checking the condition and functionality of fire extinguishers on a regular basis using proper procedures and tools. In this ultimate guide, we will explain everything you need to know about fire extinguisher inspections and how to perform them with ease and confidence using Certainty Software. […]

SWPPP: A Guide on What It Is, Why It Matters, and How to Build One

SWPPP is a document that describes how your business will prevent or reduce stormwater pollution from your activities. In this blog post, you will learn how to create, comply, monitor, and adapt SWPPP for different industries. […]

FSSC 22000: The Ultimate Guide to Certification and its Benefits

FSSC 22000 is a globally recognized food safety management system certification that can boost your business in the food industry. This blog post will explain what FSSC 22000 is, and how to get and keep it. […]

The Power of Integrated Risk Management: Enhancing Organizational Success

Do you want to learn how to manage risks effectively and efficiently in today’s complex and dynamic business environment? In this blog post, we will show you how integrated risk management (IRM) can help you achieve organizational success. We will also explain how Certainty Software can support your IRM initiatives. Read on to find out more. […]

8 Effective Risk Management Techniques for Today’s Challenges

From Bowtie Analysis, to training programs, discover 8 of the most effective risk management techniques and strategies your operations can implement quickly. Learn to how to better manage your risk mitigation efforts with this blog post. […]

What is TRIR and How It’s Calculated

TRIR is a key safety metric that measures the frequency of workplace incidents and injuries. Improving your TRIR score can help you reduce costs, enhance reputation, and promote a positive safety culture. Learn more about TRIR and how to calculate it in this blog post. […]

How to Use Key Risk Indicators to Manage Risks and Improve Performance

Risk is inevitable in any business, but it can also be a source of opportunity and competitive advantage. You may have tried to use traditional risk management approaches, where each business unit leader is responsible for managing risks within their area of responsibility. Discover how to mitigate risk with Key Risk Indicators. […]

ISO 19011: A Comprehensive Guide to Quality Management Auditing

ISO 19011 is a guidance document that helps organizations to audit their management systems and improve their performance and credibility. In this blog post, you will learn what ISO 19011 is, how it relates to other ISO standards, and how to implement it successfully with best practices and tips. […]

Understanding Workplace Near Miss Events: Types and Prevention Strategies

Near miss events are situations where an accident or injury was narrowly avoided, but could have happened under slightly different circumstances. They are also known as close calls, near hits, or near accidents. Near miss events are common in the work environment. These events can occur in any setting or industry, but they are often underreported or ignored. However, near miss events can provide valuable insights into potential hazards and risks that exist in the workplace, and how to prevent them. […]

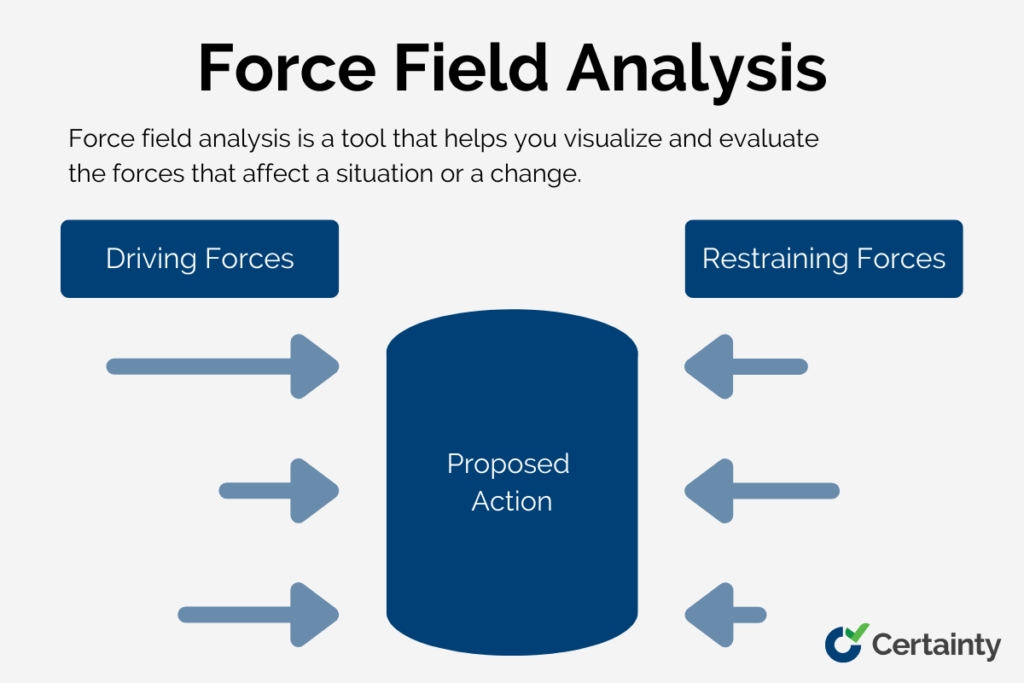

How to Use Force Field Analysis to Manage Change and Improve Performance

Force field analysis is a change management tool that helps you analyze the factors that support or oppose a proposed change. It was developed by Kurt Lewin, a social psychologist who introduced the field theory and the theory of change. In this blog post, we will explain what force field analysis is, how it works, and how you can use it to make better decisions. You will learn how to define the current and desired states of a situation, identify and score the driving and restraining forces, draw a force field analysis diagram, and develop an action plan based on the results. […]