Table of contents

You may not be aware that process safety events cost the world economy more than $20 billion per year. These catastrophes not only cause deaths, injuries, and environmental harm, but they also harm a company’s reputation, output, and revenue. Process safety is therefore a crucial component of any industrial operation.

Process safety focuses on locating and controlling potential risks and hazards in industrial processes. However, many companies have trouble putting in place efficient process safety management systems. They frequently lack the knowledge, materials, or equipment necessary to carry out thorough hazard identification and risk assessment. HAZOP analysis can help with it.

Using a HAZOP study, it is possible to predict potential risks and operational problems in industrial processes. It is founded on the idea of deviation analysis, which is the act of considering what might occur if a process deviates from how it was meant to be designed or operated. Using a diverse team and a systematic methodology, HAZOP analysis can assist you in identifying hidden or unanticipated dangers that other techniques might otherwise miss.

What is a HAZOP Analysis?

In order to increase the security and dependability of chemical engineering and facilities, Imperial Chemical Industries (ICI) created the risk analysis method known as HAZOP (Hazard and Operability) analysis in the 1960s. Since then, it has been widely used in a variety of sectors, including oil and gas, pharmaceuticals, power generation, and nuclear

Enhancing safety, preventing accidents, and increasing process effectiveness are the main goals of HAZOP analysis. It accomplishes this by detecting potential risks and operational issues that can result from changes in the circumstances or parameters of the process. A possible deviation might, for instance, involve a change in the flow rate, temperature, pressure, level, or composition of a process component.

HAZOP analysis has various advantages over other hazard identification and risk assessment methodologies, including:

- It is proactive and preventive in nature, detecting dangers before they produce accidents or incidents.

- It is comprehensive in that it addresses all potential scenarios that could disrupt the process.

- It is inventive and creative in that it generates new ideas and ways to better the process.

- It is collaborative and participative in nature, with a broad team of experts and stakeholders contributing their ideas and knowledge.

Key Objectives of the HAZOP Analysis

HAZOP analysis’ major goals are to find deviations, analyze the implications, and provide protections for each process component or node.

Assume you’re investigating a procedure that includes heating a liquid in a reactor vessel. You would begin by defining the nodes (for example, reactor vessel, heating system) and process parameters (for example, temperature, pressure). Then, for each node and parameter combination, you would utilize guide words (e.g., high, low, no) to generate deviations (e.g., high temperature, low pressure). Following that, you would assess the severity and likelihood of each deviation’s probable repercussions (e.g., fire, explosion). Finally, you would recommend safeguards (such as alarms and valves) to prevent or mitigate the consequences of each deviation.

The following are the major objectives of HAZOP analysis:

- Identify potential deviations: What could go wrong in the process?

- Examine the repercussions: What are the likely outcomes and effects of the deviations?

- Suggestions for safeguards: What may be done to avoid or reduce deviations?

However, fulfilling these goals is not always simple or easy. Identifying deviations might be difficult at times due to the process’s complexity or uncertainty. Assessing repercussions might be challenging at times due to a lack of data or information on probable outcomes. Recommending precautions is often unrealistic due to the cost or feasibility of implementing them. As a result, it is critical to undertake HAZOP analysis in a methodical and structured manner, as we shall address in the next section.

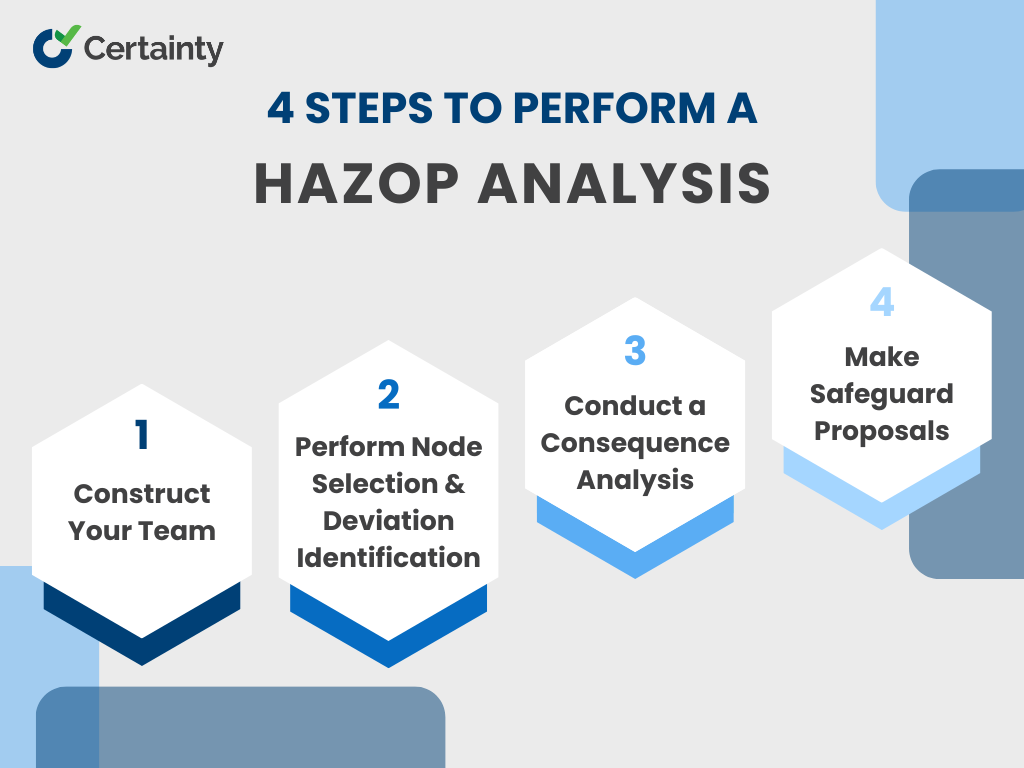

How to Conduct a HAZOP Analysis

You may be asking how to do HAZOP analysis in practice now that you have a basic idea of what it is and why it is necessary. How do you use the HAZOP technique to detect possible risks and operational concerns in your own processes? What processes are included in a HAZOP analysis, and what tools and approaches can be used to help them?

Step 1: Team Composition

The membership of the team is an important aspect of a successful HAZOP analysis. A HAZOP team should be comprised of a varied group of specialists and stakeholders with varying viewpoints and expertise in the process. Your team should ideally contain the following roles:

- A leader or facilitator leads the team through the HAZOP technique, ensures objectives are accomplished, and documents the results.

- A process engineer is someone who provides technical advice on process design, operation, and performance.

- An operator who has hands-on experience in process execution, control, and maintenance.

- A safety specialist who may advise on potential hazards, risks, and laws.

- Other key stakeholders, such as quality assurance, environmental, and management representatives, offer feedback on the process needs implications, and expectations.

To ensure effective collaboration among the team members, it is important to establish clear communication channels, roles, and expectations. It is also important to provide adequate training and preparation for the team members on the HAZOP methodology and tools. Furthermore, it is important to schedule regular meetings and reviews to monitor the progress and quality of the HAZOP analysis.

Step 2: Node Selection and Deviation Identification

To begin the second step of the HAZOP method is to choose and define the nodes for each process. A node is a particular process component or site at which deviations can occur. A node could be a pipe section, a valve, a pump, or a tank, for example. The process flow diagram (PFD), which depicts the layout and connectivity of the process components, should be used to guide node selection. A good node selection should encompass all key aspects of the process without being overly broad or very limited.

Following that, you must determine the deviations for each node. A deviation is a divergence from a node’s intended or typical operation. A deviation could be a change in the flow rate, temperature, pressure, level, or composition of a process component, for example.

The deviation should be identified using guide words (GW), which are standard terminology that indicates how a parameter can deviate. Some examples of common guide words are:

- no (complete loss)

- more (increase)

- less (decrease)

- part of (only some components)

- reverse (opposite direction)

- as well as (contamination)

- other than (different kind).

A good deviation identification should include all probable events that could influence the node without being excessively broad or narrow.

The table below illustrates how nodes and deviations are chosen and discovered for a basic operation that involves boiling water in a tank:

| Node | Parameter | Guide Word | Deviation |

| Tank | Temperature | No | No Temperature |

| Tank | Temperature | More | High Temperature |

| Tank | Temperature | Less | Low Temperature |

| Tank | Pressure | No | No Pressure |

| Tank | Pressure | More | High Pressure |

| Tank | Pressure | Less | Low Pressure |

| Tank | Level | No | No Level |

| Tank | Level | More | High Level |

| Tank | Composition | As well as | Water Contaminated |

| Tank | Composition | Other than | Water Replaced |

It is beneficial to utilize some strategies or tricks to optimize the node selection and deviation identification processes, such as:

- Make use of PFDs that are clear, up-to-date, and accurate.

- Break down large processes into smaller sub-processes or pieces.

- For parameters, use consistent and suitable wording and units.

- Use relevant and applicable guidance phrases for each parameter.

- Use brainstorming tools to produce unique and comprehensive deviations.

Step 3: Consequence Analysis

The third step in the HAZOP analysis process is to assess probable repercussions of identified deviations. A consequence is an outcome or effect that occurs as a result of a deviation. A consequence could be an injury, an environmental impact, a product defect, or a loss of production. The severity and likelihood of the consequences should be used to evaluate them.

- Severity is the degree of harm or damage caused by a consequence. Severity can be measured by using scales such as minor (no harm), moderate (some harm), major (significant harm), or catastrophic (extreme harm).

- Likelihood is the probability or frequency of occurrence of a consequence. Likelihood can be measured by using scales such as rare (very unlikely), unlikely (unlikely), possible (likely), or probable (very likely).

A good consequence evaluation should take into account both the short-term and long-term impacts of each deviation. It should also take into account both direct and indirect effects on employees, the environment, and business operations. To aid with consequence analysis, tools such as fault tree analysis (FTA) or event tree analysis (ETA) are useful. These are graphical methods that explain how deviations can result in repercussions.

The table below illustrates how some of the variances identified for the simple process of heating water in a tank are evaluated in terms of consequences:

| Deviation | Consequence | Severity | Likelihood |

| No Temperature | Water not heated | Minor | Rare |

| High Temperature | Water boils and overflows | Moderate | Unlikely |

| High Temperature | Water vaporizes and causes pressure build-up | Major | Possible |

| High Temperature | Water reacts with tank material and forms corrosive products | Major | Possible |

| High Pressure | Tank ruptures and releases water and steam | Catastrophic | Probable |

| No Level | Tank empty and heating system damaged | Moderate | Unlikely |

| Low Level | Tank partially empty and heating system inefficient | Minor | Possible |

Step 4: Safeguard Recommendations

The final phase in HAZOP analysis is to provide suggestions and implement safeguards to reduce or eliminate identified hazards. A safeguard is a method of preventing or reducing the occurrence or impact of a deviation. A safeguard could be anything from an alert to a valve, a sensor, or a procedure. The recommendation for a safeguard should be based on three criteria: effectiveness, feasibility, and cost.

- Effectiveness is the degree to which a safeguard can prevent or mitigate a deviation. Effectiveness can be measured by using scales such as high (very effective), medium (somewhat effective), low (slightly effective), or none (not effective).

- Feasibility is the degree to which a safeguard can be implemented or maintained. Feasibility can be measured by using scales such as easy (no difficulty), moderate (some difficulty), difficult (high difficulty), or impossible (cannot be done).

- Cost is the amount of resources or money required to implement or maintain a safeguard. Cost can be measured by using scales such as cheap (low cost), affordable (reasonable cost), expensive (high cost), or prohibitive (unaffordable cost).

A decent safeguard recommendation should take into account the trade-offs and balances between these objectives. It should also take into account the engineering hierarchy of controls, which is a structure for ranking safeguards based on their effectiveness and preference. There are five levels in the engineering hierarchy of controls:

- Elimination: removing the hazard or deviation completely.

- Substitution: replacing the hazard or deviation with a less harmful one.

- Engineering: designing or modifying the process or equipment to reduce the hazard or deviation.

- Administrative: establishing policies, procedures, or training to reduce the hazard or deviation.

- Personal protective equipment (PPE): providing protective clothing or devices to reduce the hazard or deviation.

The table below illustrates how precautions are suggested for some of the variations discovered in the simple process of heating water in a tank:c

| Deviation | Safeguard Recommendation | Effectiveness | Feasibility | Cost |

| No Temperature | Install a thermostat to monitor and control the temperature. | High | Easy | Affordable |

| High Temperature | Install a pressure relief valve to release excess steam. | High | Moderate | Expensive |

Benefits and Importance

Accident Prevention

One of the most significant advantages and benefits of HAZOP analysis is that it helps prevent accidents and occurrences that could have disastrous effects on your business. HAZOP analysis can lower the possibility and effect of catastrophic occurrences by detecting and managing possible hazards and operational difficulties.

- Fires, explosions, or chemical releases could result in death, injury, or environmental damage.

- Product flaws, quality difficulties, or customer complaints may have an impact on your company’s reputation, market share, or customer satisfaction.

- Productivity, efficiency, and profitability may suffer as a result of production losses, downtime, or equipment damage.

HAZOP analysis has been shown to be successful in averting catastrophic accidents and incidents in a variety of sectors. For example, in the design of the Apollo spacecraft that landed on the moon in 1969, HAZOP analysis was utilized to identify and eliminate potential hazards. After the 1988 Piper Alpha oil platform catastrophe, which killed 167 people and cost $3.4 billion in damages, HAZOP analysis was employed to prevent repeat tragedies.

Regulatory Compliance

Another advantage and significance of HAZOP analysis is that it can assist you in complying with relevant legislation and standards such as OSHA or ISO that emphasize the significance of hazard identification and risk reduction in industries. You may demonstrate your commitment to process safety and meet the requirements of various agencies by undertaking HAZOP analysis.

HAZOP analysis can assist you in avoiding penalties, fines, or legal action as a result of noncompliance with regulations and standards. It can also assist you in gaining a competitive advantage, such as:

- Improving your consumer, investor, or regulatory reputation and credibility.

- Meeting international criteria improves your market access and potential.

- Reducing your insurance premiums or liability costs by demonstrating your risk management capabilities.

Operational Excellence

The third advantage and significance of HAZOP analysis is that it can increase operational performance and excellence by improving process efficiency, reliability, and quality. It can also help you optimize your process parameters and conditions by detecting and resolving potential operational concerns, such as:

- Minimizing shutdowns, deviations, or losses to reduce waste, energy consumption, or pollution.

- Maximizing process output or utilization to increase yield, throughput, or capacity.

- Improving product quality, consistency, or specification through process control and stability.

HAZOP analysis can also assist you in identifying areas for process improvement or innovation, such as:

- Introducing innovative technology, methods, or solutions that increase the safety or efficiency of a process.

- Creating new products, services, or markets to suit the needs or desires of customers.

- Adding additional value, revenue, or profit streams through the use of process capabilities or assets.

With HAZOP, you are on a better path to achieving operational excellence and gaining a competitive edge by providing the following benefits:

- Increasing client pleasure and loyalty through the delivery of high-quality goods or services.

- Increasing your productivity and profitability through expense reduction or revenue growth.

- Increasing your adaptability and resilience by anticipating and handling changes or uncertainty.

Challenges and Considerations

Resource Intensity

Despite its benefits and significance, HAZOP analysis presents several obstacles and issues that you should be aware of when performing it. One of the most significant issues is the resource intensity of HAZOP analysis, which refers to the amount of time and resources required to conduct a thorough HAZOP analysis.

30+ Audit and inspection checklists free for download.

HAZOP analysis can be a time-consuming and complex procedure that includes a number of processes and activities, such as:

- Creating process documentation such as PFDs, operating manuals, and data sheets.

- Choosing members of the HAZOP team and providing them with training and tools.

- Conducting HAZOP sessions and documenting the outcomes and recommendations.

- Implementing the recommendations and testing their efficacy.

HAZOP analysis can also be a costly and time-consuming process that necessitates significant effort and dedication, such as:

- A sufficient budget, manpower, and equipment are allocated for the HAZOP analysis.

- Setting aside enough time, frequency, and duration for HAZOP sessions.

- Managing potential disputes, disagreements, or biases among members of the HAZOP team.

To overcome these obstacles, the HAZOP analysis process must be streamlined while remaining effective. Some approaches include:

- Choosing the most critical or dangerous processes or nodes for HAZOP analysis.

- Using software tools or apps to help with data collecting, deviation generation, outcome evaluation, or safeguard recommendation.

- Defining the HAZOP analysis’s objectives, scope, and criteria.

Human Factors

Another HAZOP analysis problem and concern is the human aspects that can affect the quality and reliability of the HAZOP analysis.

Human variables can have an impact on HAZOP analysis in both positive and negative ways. Human factors, for example, can improve HAZOP analysis by:

- Providing innovative or helpful deviations or precautions through imagination, intuition, or experience.

- Giving comments, assistance, or motivation to boost team collaboration or morale.

- Providing opportunities for learning, improvement, or adaptability that could boost team competence or confidence.

These same human variables can also hamper your HAZOP analysis by:

- Causing human error, such as errors, oversights, or omissions, which may result in erroneous or incomplete deviations or safeguards.

- Causing cognitive distortions such as anchoring, confirmation bias, or groupthink, which may result in irrational or illogical deviations or safeguards.

- Causing social pressures such as conformity, authority, or group polarization, which may result in skewed or compromised deviations or protections.

Streamlining the HAZOP Analysis Process

One of the problems of conducting HAZOP analysis, as previously said, is the resource intensity, which refers to the time and resources required to collect, track, and report accurate and powerful HAZOP data. To tackle this difficulty, you will require dependable and user-friendly audit and inspection software that can assist you in streamlining your HAZOP analysis process while assuring compliance, lowering risk, and boosting performance.

You can develop and customize your own audit and inspection HAZOP forms with Certainty Software, or you can utilize ready-made templates from the library. HAZOP sessions can also be conducted online or offline utilizing the mobile app or web-based software. Furthermore, you may create professional and detailed HAZOP reports that include graphs, charts, and photographs. The analytics dashboard also allows you to handle remedial actions and monitor performance indicators. Finally, you can work with your HAZOP team to securely communicate data across your organization.

If you’re ready to learn more about how Certainty Software can support your HAZOP goals – and overall safety goals, don’t hesitate to reach out to us for a 1-on-1, no obligations demo.

You might also be interested in: