Table of contents

Safety isn’t just important in the corporate world of today; it’s essential to success. The defining characteristic that distinguishes strong organizations from the competition is the mastery of leading and lagging safety indicators. These indications have the power to protect your bottom line in addition to potentially saving lives.

According to the Occupational Safety and Health Administration OSHA, employers who have effective safety and health management systems can decrease workplace accidents and illnesses by 40%. This fact is eye-opening and highlights the importance of implementing such systems. Consider the effect such savings would have on the success and standing of your company in the Department of Labor’s records.

Beyond the monetary advantages, however, these indicators are the key to the success of businesses that succeed at safety precautions. They offer a road map for enhancing safety while simultaneously driving unmatched efficiency and profitability, which, in turn, boosts customer satisfaction.

What are Leading and Lagging Safety Indicators?

Metrics guide your company’s actions in managing workplace safety, like a choreographer directing a dance on the risk management stage. Lagging and leading safety indicators have different functions in promoting occupational health and safety.

Lagging Safety Indicators

Looking back at your safety journey, lagging safety indicators record past accidents as historical records. The data includes the number of recorded incidents, total hours missed because of work injuries, workplace accidents, and close calls. These measurements provide a retroactive prism through which we might assess the past while addressing occupational injuries and illness.

These signs, however, are much more than just artifacts from the past. They offer insightful analyses of previous safety performance, highlighting patterns, trends, and prospective areas for development that necessitate continuous improvement. Businesses can use past lessons to make proactive changes to safety initiatives, preventing injury and creating a safer future.

Leading Safety Indicators

Prevention is the key to success in the area of workplace safety. Leading safety indicators are early warning signs.

They help businesses anticipate and prevent safety hazards. These indicators are used before hazards become incidents. Incidents can lead to compensation claims.

These safety measures, like training, audits, surveys, and meetings, protect workers and encourage a culture of safety awareness. They are leading businesses toward a safer future by promoting a safety culture that focuses on preventing slips, trips, and falls. This helps companies succeed in the long run and takes care of its workers’ well-being by addressing safety concerns.

How do Leading and Lagging Safety Indicators Differ?

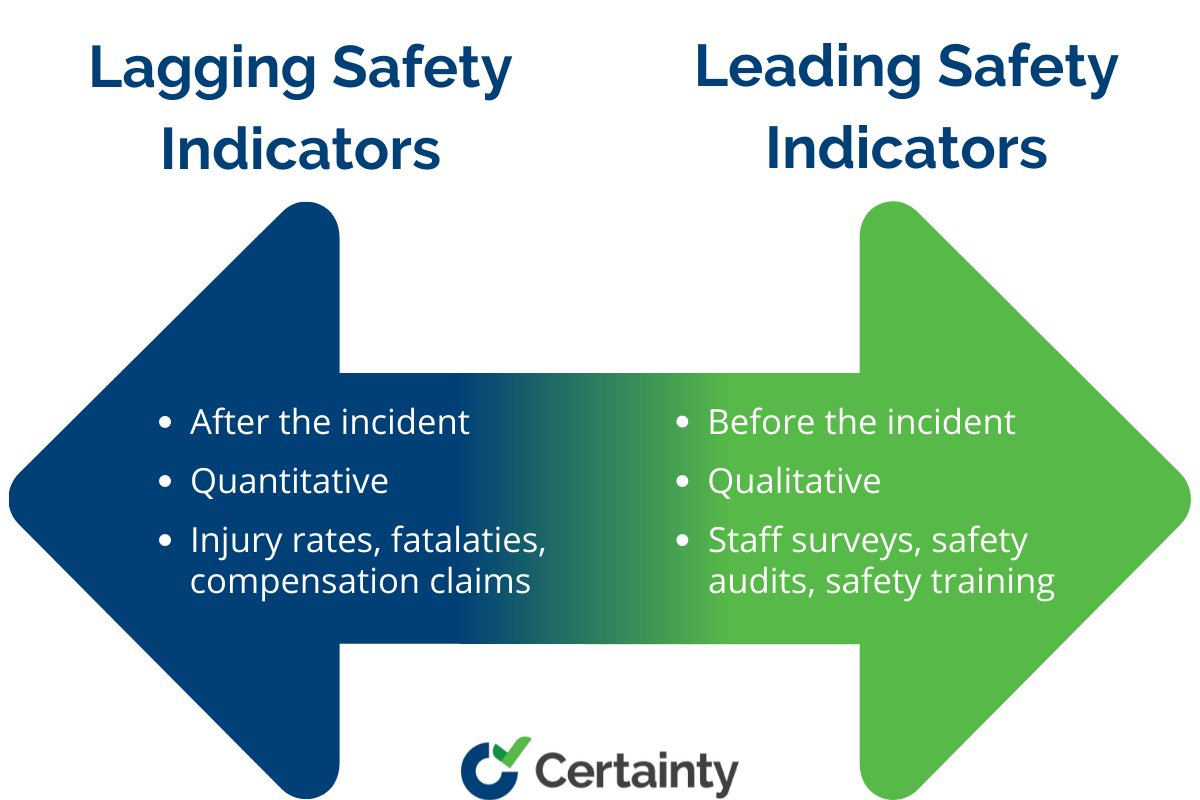

The biggest difference between leading and lagging safety indicators is time. Lagging indicators are measured after incidents while leading indicators are measured before problems to predict the future.

The measurement itself also differs, with lagging indicators more quantitative and leading indicators more qualitative. Lagging indicators provide concrete information on injuries, deaths, and compensation claims. Leading indicators focus on employee feedback and near misses to ensure workplace safety.

Where are Leading and Lagging Indicators Similar?

Where these indicators overlap is in the overall purpose: Making your business safer.

Consider lagging indicators. The reports display past events. However, they cannot alter what has already happened.

This remains true even if future processes are modified. And depending on the severity of the incidents, companies could be facing significant losses of both time and money.

In the construction industry, safety indicators can work together to improve safety outcomes. Here’s a real-world example. Leading indicators, meanwhile, provide insight into what might happen. Additionally, they allow companies to create proactive initiatives that improve workplace safety and drive continuous improvement.

Where they fall short, however, is hard data. Staff surveys and audits provide a general idea of safety. However, they do not provide enough data to determine if changes will have an impact.

However, organizations can benefit from the best of both worlds by using both safety-leading indicators and lagging indicators together. That is concrete information about what has previously occurred paired with indicators of what is most likely to occur. Together, this enables them to pinpoint high-risk locations with safety program initiatives and pinpoint the underlying problems.

Examples of Leading and Lagging Indicators in Action

In the construction industry, safety indicators can work together to improve safety outcomes. Here’s a real-world example. This example is based on a study that examined the connection between leading and lagging indicators in construction projects. The study used data from 47 projects and was published in Safety Science, highlighting the importance of personal protective equipment.

The number of injuries and first aid injuries were the trailing indications, while the number of site inspections and toolbox talks were the leading ones. They tested whether a higher proportion of leading indicators resulted in a decrease in the frequency of lagging indicators using statistical models.

The findings revealed a significant inverse association between leading and lagging markers, particularly for first-aid injuries. Therefore, first-aid injuries were less frequent on projects with more site visits and toolbox discussions than on projects with fewer of these activities. However, because the effect sizes were so tiny, it is possible that additional factors also have an impact on safety performance.

The number of injuries and first aid injuries were the trailing indications, while the number of site inspections and toolbox talks were the leading ones. They tested whether a higher proportion of leading indicators resulted in a decrease in the frequency of lagging indicators using statistical models.

The findings revealed a significant inverse association between leading and lagging markers, particularly for first-aid injuries. Therefore, first-aid injuries were less frequent on projects with more site visits and toolbox discussions than on projects with fewer of these activities. However, because the effect sizes were so tiny, it is possible that additional factors also have an impact on safety performance.

30+ Audit and inspection checklists free for download.

How to Combine Leading and Lagging Indicators for Better Safety Outcomes

Here are some practical tips and steps to help you combine leading and lagging indicators for better safety outcomes:

- Determine the lagging indicators that capture your strategic goals by starting with them. If you want to reduce lost-time injuries, the lost-time injury frequency rate (LTIFR) can be a useful indicator.

- Track the leading indicators that have an impact on your trailing indicators on a regular basis. To lower the LTIFR, you can examine the number of safety checks, audits, observations, training, or actions taken to resolve issues. These factors contribute to reducing the LTIFR.

- To monitor and understand patterns and connections for occupational health and safety, use a balanced scorecard or dashboard. This will help you track both leading and lagging indicators.

- Look for trends, correlations, or gaps in the data from both leading and trailing indicators. For instance, you may undertake statistical research and produce charts or graphs that demonstrate how your leading indicators impact your trailing indicators using a program like Excel or Tableau.

- Take action and modify your procedures or strategies in accordance with the revelations from your data analysis. If improving a certain leading indicator significantly helps your lagging indicator, you can allocate more time or money to it. You can remove a leading indicator if it doesn’t harm your lagging indicator and helps prevent work injuries.

- Make sure your leading and lagging indicators are consistent with your goals and appropriate for the situation by periodically reviewing and updating them. You may, for instance, check to see if your indicators are still accurate, trustworthy

Enhancing Safety with Certainty Software

The secret to effective control of both leading and lagging safety indicators is Certainty Software. It makes data gathering simpler by enabling staff members to record safety observations, take part in safety meetings, and finish safety audits in real time. This encourages participation and guarantees up-to-date, accurate data. Ultimately leading to better corrective actions, and reduced safety issues.

With Certainty, you can improve your data analysis and reporting capabilities. This allows you to identify trends, correlations, and areas for improvement. It also helps bridge the gap between leading and lagging indicators.

Additionally, Certainty Software streamlines work delegation and monitor development, converting insights from leading indications into noticeable advancements in lagging indicators. It is a scalable solution that encourages adherence to legal and regulatory standards, demonstrates a dedication to health and safety, safeguards financial interests, and promotes a safer working environment.

Ready to experience the power of Certainty Software for yourself? Book a demo today to see how it can transform your safety management.

Try our free Facility Safety Inspection Checklist.

You may also be interested in:

PPE Inspections: What They Are and Why You Need Them

Field Level Hazard Assessments: What They Are (And Why They Matter)