Personal protective equipment (PPE) saves lives. Consider the humble hard hat: First introduced in 1919 by Edward W. Bullard, who designed the hat to resemble his doughboy army helmet, the hard hat helped reduce work site deaths by two-thirds between 1970 and 2016. PPE also saves money: Companies can save over $30,000 for every medically-consulted injury they avoid. Today, PPE options are many and varied. From eye and ear protection to full-body options that provide complete coverage, there’s a PPE solution for every use case. But in the same way that on-site machinery needs regular maintenance, companies must perform regular PPE inspections to ensure that protective clothing continues to provide consistent defense against potential hazards.

In this piece, we’ll break down the basics and types of PPE and then dive into the what, when, and how of an inspection to help your company keep staff safe.

What is PPE?

According to OSHA, PPE is “equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. “

Put simply. PPE is anything staff wear that helps reduce total risk. Along with industry-specific governing bodies, OSHA describes the type of PPE required for differing applications such as welding, cutting, and handling hazardous materials.

What are the Different Types of PPE?

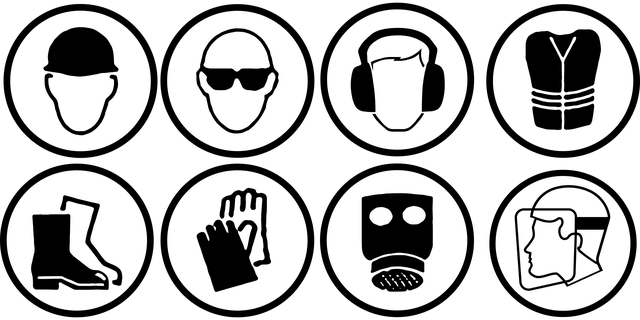

Anything worn to protect the body during work can be classified as PPE, but personal protective equipment is often broken down into seven broad types:

- Eyewear and face protection

Eye protection and face protection include safety glasses, impact goggles, and face shields.

- Hand protection

Latex, chemical resistant, insulated and wire mesh are all examples of hand protection PPE.

- Body protection

Tradition cotton or polyester coveralls provide body protection for general work, while flame-resistant or barrier-based options help reduce the risk of working with reactive chemicals or biological agents. Harnesses, meanwhile, can help with fall protection.

- Respiratory protection

Respiratory protection includes surgical masks and N-95 respirators along with half-mask and full-face respirators.

- Hearing protection

Disposable earplugs, hearing bands, and noise-reducing earmuffs help protect workers from loud and consistent noises in the workplace.

- Foot protection

Steel-toed boots are the most common type of protective footwear, but depending on the job site other options such as closed-toed shoes or slip-on covers may be required.

- Head protection

Hardhats are the most common form of head protection on the worksite. Headbands and other head coverings can also reduce total risk.

What is a PPE Inspection?

A PPE inspection is an assessment of the protective equipment for potential defects or problems. If problems are identified, PPE should not be used until the issues can be rectified — if this is impossible, the PPE should be discarded. For example, even appropriate PPE can lose its effectiveness after regular exposure to light, heat, or chemicals. Consider battery acid. If this liquid spills on coveralls, it will eat through the material in a matter of days, rendering them useless. Regular inspections are critical to avoid this risk.

When Should PPE be Inspected?

Ideally, any required PPE should be inspected before and after every use as part of daily, pre-work hazard assessments. It should be cleaned and stored properly to help maximize its useful life, and any defects should be reported.

More in-depth PPE inspections should also take place approximately once per month to evaluate the current state of PPE in the organization. These in-depth inspections allow companies to determine if they have sufficient amounts of usable PPE and also pinpoint areas where they may need to purchase more protective equipment to ensure it is readily available.

30+ Audit and inspection checklists free for download.

Who Should Conduct the Inspection?

In the case of a day-to-day inspection, workers can perform the inspection themselves and note any defects. For more in-depth inspections, team leaders or safety team members should be in charge of organizing and carrying out the inspection to ensure all PPE is effectively assessed.

General Requirements for a PPE Inspection

At its most basic, a PPE inspection focuses on ensuring that protective equipment is still performing its intended function. For daily use inspections, this broad definition is sufficient: If workers see obvious damage to PPE or can’t find enough pieces of PPE to protect all staff working on-site, they can report the issue to their supervisors.

For more in-depth inspections, meanwhile, it’s worth using a PPE inspection checklist that describes exactly what to look for when assessing equipment. Consider a set of coveralls. While daily inspection might not reveal any obvious damage, a closer look may uncover issues with the fit and function of the PPE — such as loose buckles or corrosion — that suggest the need for replacement, either individually or at scale.

Ultimately, the goal of a PPE inspection is to identify issues with any mandated safety equipment and help build a safety culture that prioritizes protection in the work environment over simply getting the job done.

Bottom line? Regular and in-depth PPE inspections save time, money — and lives.

You may also be interested in:

Keep it Seen, Keep it Safe: The Importance of Construction Safety Observations