Table of contents

In today’s competitive and dynamic business environment, businesses need to constantly improve their processes and performance to stay ahead of the curve. Process improvement methodologies are frameworks that help companies to identify and eliminate inefficiencies, defects, and waste in their operations. One of the most widely used and effective methodologies is the DMAIC process.

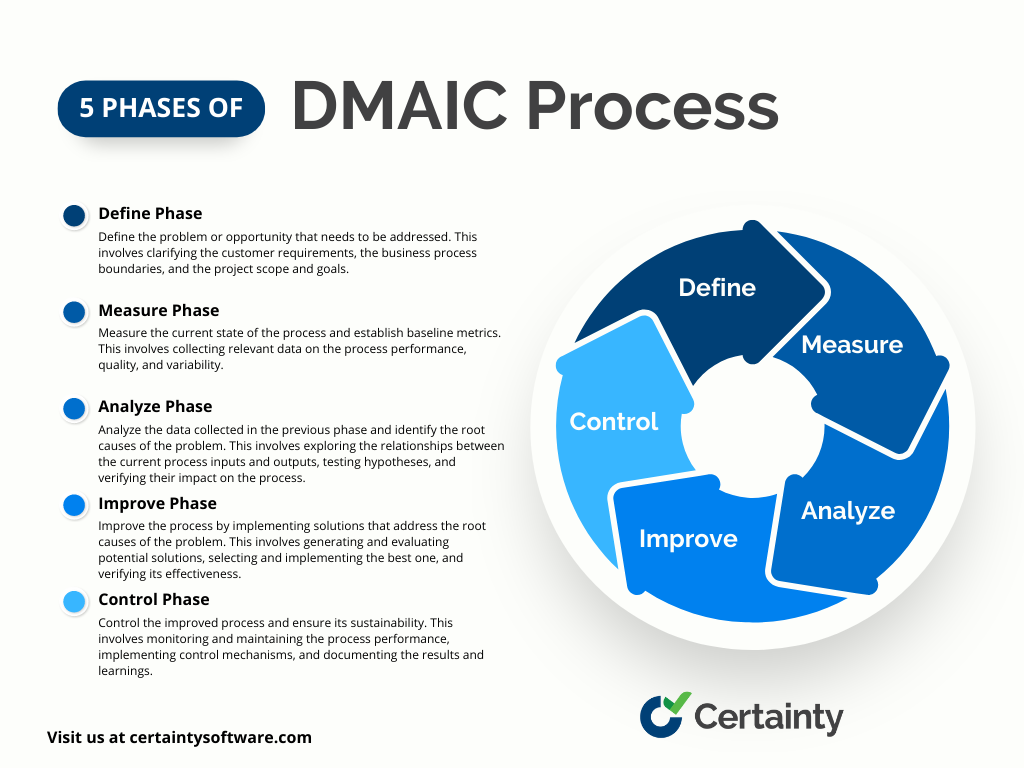

The DMAIC process is a structured and data-driven approach for achieving continuous improvement and operational excellence. It stands for Define, Measure, Analyze, Improve, and Control. These are the five phases that guide the problem-solving and improvement efforts of businesses. By following the DMAIC process, you can align your company’s processes with organizational goals and drive efficiency across its functions.

In this comprehensive guide, we will explore the DMAIC process in detail and show you how to implement it in your business. We will also compare it with another popular methodology, DMADV, and discuss the key differences between them. Finally, we will highlight the benefits of implementing DMAIC in your business and share some tips and best practices for overcoming implementation challenges.

What is the DMAIC Process and Its Importance?

The DMAIC process is a systematic and data-driven methodology for improving existing processes and solving complex problems. It is derived from the Six Sigma philosophy, which aims to reduce variation and defects in processes and achieve near-perfection. The acronym DMAIC stands for:

- Define

- Measure

- Analyze

- Improve

- Control

Understanding the DMAIC Phases

The DMAIC process consists of five phases that guide the improvement efforts of enterprise-level businesses. Each phase has its own objectives, activities, and deliverables that ensure a structured and rigorous approach. Let’s take a closer look at each phase and what it entails.

Define Phase

The first phase of the DMAIC process is to define the problem or opportunity that needs to be addressed. This involves clarifying the customer requirements, the business process boundaries, and the project scope and goals. The main activities in this phase include:

- Developing a problem statement that describes the gap between the current and desired state of the process

- Creating a project charter that outlines the project objectives, scope, timeline, budget, team roles and responsibilities, and expected benefits

- Mapping the high-level process flow and identifying the key inputs and outputs

- Conducting a stakeholder analysis and engaging relevant stakeholders throughout the project

Measure Phase

The second phase of DMAIC is to measure the current state of the process and establish baseline metrics. This involves collecting relevant data on the process performance, quality, and variability. The main activities in this phase include:

- Defining the critical-to-quality (CTQ) characteristics that reflect the customer needs and expectations

- Developing an operational definition for each CTQ characteristic that specifies how it will be measured

- Designing a data collection plan that specifies what data will be collected, how, when, where, and by whom

- Validating the measurement system to ensure its accuracy, precision, and reliability

- Collecting and summarizing the data using appropriate tools and techniques

30+ Audit and inspection checklists free for download.

Analyze Phase

The third phase of the DMAIC process is to analyze the data collected in the previous phase and identify the root causes of the problem. This involves exploring the relationships between the current process inputs and outputs, testing hypotheses, and verifying their impact on the process. The main activities in this phase include:

- Performing a data analysis using appropriate tools and techniques such as histograms, Pareto charts, scatter plots, correlation analysis, regression analysis, etc.

- Identifying potential root causes using tools such as fishbone diagrams, brainstorming sessions, affinity diagrams, etc.

- Prioritizing root causes using tools such as Pareto analysis, failure mode and effects analysis (FMEA), etc.

- Testing root causes using tools such as hypothesis testing, design of experiments (DOE), etc.

- Validating root causes using tools such as cause-and-effect matrix, verification matrix, etc.

Improve Phase

The fourth phase of the DMAIC process is to improve the process by implementing solutions that address the root causes of the problem. This involves generating and evaluating potential solutions, selecting and implementing the best one, and verifying its effectiveness. The main activities in this phase include:

- Generating potential solutions using tools such as brainstorming sessions, benchmarking studies, best practices research, etc.

- Evaluating potential solutions using tools such as solution selection matrix, cost-benefit analysis, risk assessment, etc.

- Selecting the best solution based on criteria such as feasibility, impact, cost, risk, etc.

- Developing an implementation plan that specifies how the solution will be executed, who will be involved, what resources will be needed, what risks will be mitigated, etc.

- Implementing the solution according to the plan and monitoring its progress and performance

- Monitoring the effectiveness of the solution using tools such as before-and-after analysis, statistical process control (SPC), etc.

Control Phase

The fifth and final phase of the DMAIC process is to control the improved process and ensure its sustainability. This involves monitoring and maintaining the process performance, implementing control mechanisms, and documenting the results and learnings. The main activities in this phase include:

- Developing a control plan that specifies how the process will be monitored, measured, and controlled to prevent deviation or deterioration

- Implementing control mechanisms such as control charts, standard operating procedures (SOPs), checklists, audits, etc.

- Training and educating process owners and operators on the new process and its controls

- Communicating and celebrating the project results and achievements with stakeholders

- Documenting the project learnings and best practices for future reference and replication

DMAIC vs. DMADV: Key Differences

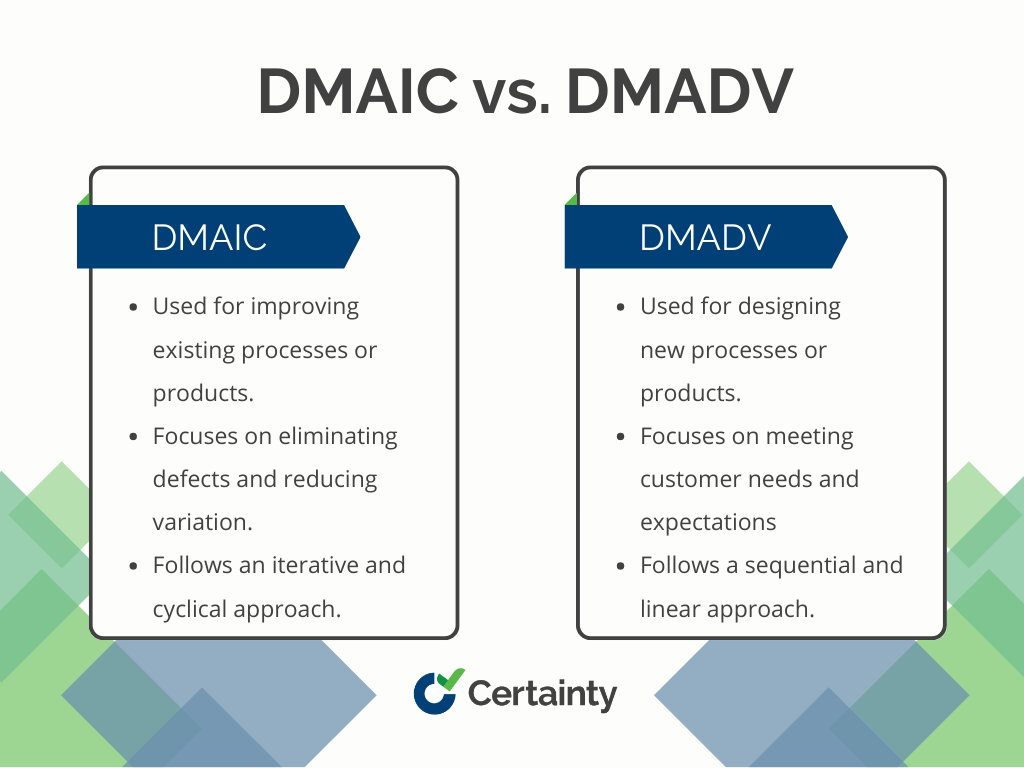

The DMAIC process is not the only methodology that can be used for process improvement and problem-solving. Another popular methodology is the DMADV process, which stands for Define, Measure, Analyze, Design, and Verify. The DMADV process is similar to the DMAIC process in some aspects, but it has some key differences that make it more suitable for certain situations and applications.

The main difference between DMAIC and DMADV is that DMAIC is used for improving existing processes, while DMADV is used for designing new processes or products. DMAIC assumes that the process or product already exists and needs to be optimized or enhanced. DMADV assumes that the process or product does not exist or needs to be radically redesigned or replaced.

Another differentiation between DMAIC and DMADV is that DMAIC focuses on eliminating defects and reducing variation in processes or products, while DMADV focuses on meeting customer needs and expectations in processes or products. DMAIC aims to achieve near-perfection in quality and performance by minimizing errors and waste. DMADV aims to achieve customer satisfaction and loyalty by maximizing value and innovation.

Something else that sets apart DMAIC and DMADV is that DMAIC follows an iterative and cyclical approach, while DMADV follows a sequential and linear approach. DMAIC allows for repeated measurement cycles, analysis, improvement, and control until the desired results are achieved. DMADV follows a one-way flow of design, development, testing, and verification until the final product or process is delivered.

The table below summarizes the key differences between DMAIC and DMADV:

Both DMAIC and DMADV are powerful methodologies that can help businesses achieve their process improvement and problem-solving goals. However, each methodology has its own strengths and limitations, and it is important to choose the right one based on the situation and application.

Benefits of Implementing DMAIC

Implementing the DMAIC process can bring significant benefits and advantages that can boost their performance and competitiveness. Some of the benefits of implementing DMAIC are:

Improved operational efficiency

By following the DMAIC process, companies can identify and eliminate the sources of inefficiency, waste, and variation in their processes. This can result in faster cycle times, higher throughput, lower rework, and better resource utilization.

Enhanced quality control

Businesses can ensure that their processes and products meet or exceed customer requirements and expectations. This can result in lower defects, higher customer satisfaction, lower warranty costs, and higher reputation.

Reduced costs

Using DMAIC can optimize a company’s processes and products to minimize the costs associated with defects, waste, variation, and inefficiency. This can result in higher profitability, lower operating expenses, and higher return on investment.

Driven continuous improvement

By following the DMAIC process, businesses can foster a culture of continuous improvement and innovation in their organizations. This can result in higher adaptability, agility, and resilience to changing customer needs and market conditions.

Example of DMAIC implementation

To illustrate these benefits, let’s look at an example of a business that has successfully implemented the DMAIC process and achieved measurable results.

Amazon is one of the most successful and innovative online retailers in the world and has applied the DMAIC process to improve its customer service and delivery processes. By doing so, the company has reported that it has reduced its customer contacts per order by 50% and increased its on-time delivery rate by 20% through Six Sigma and DMAIC initiatives since 2013.

Implementation Challenges

Implementing the DMAIC process can be challenging and complex. There are many factors and variables that can affect the success and outcome of DMAIC projects. Some of the common challenges that enterprise-level businesses may face during DMAIC implementation are:

Project selection

Choosing the right project to apply the DMAIC process is crucial for achieving the desired results and benefits. However, selecting the right project can be difficult and time-consuming, as it requires a clear understanding of the business objectives, customer needs, process performance, and improvement potential. A poorly selected project can result in wasted resources, low impact, and low return on investment.

Team collaboration

Working as a cross-functional team is essential for executing the DMAIC process effectively and efficiently. However, collaborating as a team can be challenging and problematic, as it involves dealing with different personalities, perspectives, opinions, and agendas. A dysfunctional team can result in conflicts, misunderstandings, delays, and errors.

Data collection and analysis

Collecting and analyzing data is a key component of the DMAIC process, as it provides the basis for making data-driven decisions and improvements. But collecting and analyzing data can be challenging and tedious, as it requires a reliable measurement system, a robust data collection plan, and appropriate tools and techniques. Poor data quality, insufficient data quantity, or inappropriate data analysis can result in inaccurate or misleading conclusions and recommendations.

Change management

Implementing changes in processes or products is the ultimate goal of the DMAIC process. Yet, implementing changes can be challenging and risky, as it involves overcoming resistance, managing expectations, mitigating risks, and ensuring sustainability. Poor change management can result in failed implementation, low adoption, or backsliding.

How to Overcome the Challenges of Implementation

To ensure successful DMAIC implementation, businesses need to adopt some strategies and recommendations. Some of these strategies and recommendations are:

Project selection

To select the right project for DMAIC implementation, you will need to use a systematic and objective approach that considers various criteria such as business impact, customer value, process performance, improvement potential, resource availability, etc.

Assistive tools that can help with project selection are the project prioritization matrix, project screening matrix, and project scoping matrix.

Team collaboration

To collaborate effectively as a team for DMAIC implementation, establish clear roles and responsibilities, set common goals and expectations, communicate openly and frequently, resolve conflicts constructively, and leverage each other’s strengths and skills.

Some tools that can help with team collaboration are team charter, RACI matrix (Responsible-Accountable-Consulted-Informed), communication plan, and team building activities.

Data collection and analysis

To collect and analyze data accurately and efficiently for DMAIC implementation, define the critical-to-quality characteristics, develop operational definitions, design a data collection plan, validate the measurement system, use appropriate tools and techniques, and verify the results.

Tools that can help with data collection and analysis are operational definition worksheets, data collection plan templates, measurement system analysis (MSA), histograms, Pareto charts, scatter plots, correlation analysis, regression analysis, hypothesis testing, and design of experiments (DOE).

Change management

For implementing changes successfully and sustainably for DMAIC implementation, you should assess the readiness and resistance for change, engage and communicate with stakeholders, manage risks and issues, monitor and evaluate the results, and document the learnings and best practices.

Tactics that can help with change management are readiness assessment surveys, stakeholder analysis, risk assessment matrix, issue log, control chart, statistical process control (SPC), project documentation reports, etc.

Certainty Software’s Support for DMAIC Implementation

Certainty Software is a leading provider of comprehensive solutions to support DMAIC implementation in enterprise-level businesses. Certainty Software offers various tools, features, checklists, and services that can help enterprise-level businesses streamline their audit and inspection processes and ensure their compliance with various standards and regulations. Some of these offerings are:

- Measure and monitor audit and inspection performance, quality, and compliance

- Analyze and identify the root causes of performance risks

- Improve and implement solutions that address root causes and enhance audit and inspection outcomes

- Control and sustain processes and ensure their alignment with regulations, and business objectives.

You might also be interested in: