A 6S Lean Audit Checklist is a tool that helps you evaluate the implementation of the 6S method in your workplace. The sixth pillar of the 6S approach, which is a modification of the 5S system, is safety. The 6S technique attempts to establish and maintain a safe, orderly, and clean working environment that encourages output and quality.

There are six steps in the 6S method:

- Sort: Clear the workspace of anything that isn’t necessary.

- Straighten: Organize necessary goods in a way that makes them easily accessible.

- Shine: Regularly clean and check the workspace.

- Safety: Recognize and get rid of potential dangers and hazards.

- Standardize: Create guidelines and practices for upholding the initial four phases.

- Sustain: Monitor and audit the 6S practices and ensure continuous improvement.

Download the 6S Lean Audit Checklist

Purpose of a 6S Lean Audit Checklist

This checklist’s objective is to assist you in evaluating the existing condition of your workplace in light of the 6S standards.

Certainty’s 6S Lean Audit Checklist helps you to identify areas for improvement, set priorities for your actions, and keep tabs on your progress. Not only that, this checklist encourages a culture of efficiency and safety among your employees.

How to use this checklist

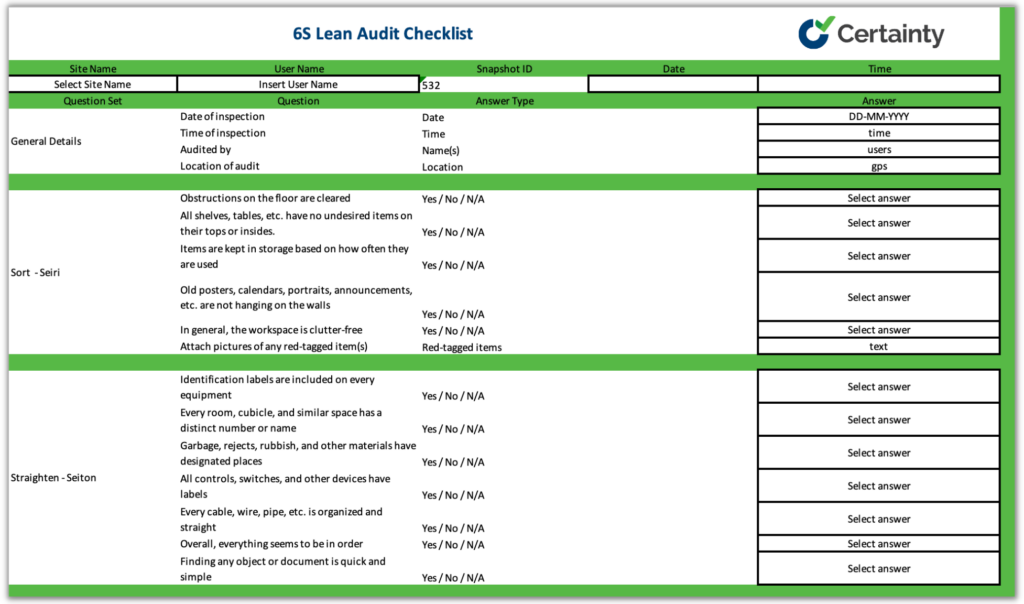

Each 6S component is broken down into its own section on this checklist. Aspects of the 6S technique that are generally covered by the checklist include management commitment, staff involvement, training, communication, and documentation. In-depth coverage of each of the six processes’ specifics, including sorting criteria, labeling systems, cleaning schedules, safety signs, standardization tools, and audit frequency, is also provided.

To use this checklist, follow these steps:

- Review each item in the checklist and mark it accordingly (Yes, No, or N/A).

- Provide comments or evidence for each item as needed.

- Calculate the total score for each section and the overall score for the checklist.

- Use a simple scoring guide of Yes = 1, No = 0.

- Develop an action plan based on the findings and assign responsibilities and deadlines.

- Review the action plan regularly and update the checklist as needed.

Scoring guide

This checklist’s grading system is based on a straightforward % approach. Divide the number of Yes items by the total number of eligible items (Yes + No), then multiply the result by 100 to get the score for each area. Divide the total of all section scores by the total number of sections to get the overall score, then multiply the result by 100.

The scores can be interpreted as follows:

90% or higher: Excellent. The workplace is neat, secure, and well-organized. You have a solid 6S culture in place and engage in continuous development.

70% to 89%: Good. Most of the time, your workplace is tidy, safe, and organized. The majority of the 6S practices have been applied, however, there is still potential for improvement.

50% to 69%: Fair. Your workplace is somewhat tidy, safe, and organized. Though you’ve used certain 6S techniques, there are still many problems and gaps that need to be resolved.

50% or less: Low. Your workplace is unclean, hazardous, and chaotic. You either haven’t adopted the 6S approach or haven’t kept it up. To make your workplace better, action needs to be taken right away.

How Certainty Improves 6S Lean Implementation

Certainty Software introduces a new dimension to 6S Lean compliance, redefining the landscape of workplace efficiency. Seamlessly integrated with the 6S Lean Audit Checklist process, our advanced software solution brings a host of benefits that effortlessly enhance your compliance measures.

By digitizing and automating key steps, Certainty Software streamlines your workflows, reduces errors, and ensures consistent adherence to protocols. Our customizable features cater to specific tasks, while real-time accessibility promotes collaboration and well-informed decision-making. Data-driven insights empower you to track trends and compliance levels, paving the way for targeted improvements.

With automated notifications, comprehensive documentation, and mobile compatibility, Certainty Software creates an environment where compliance becomes a natural extension of your daily operations.

Spend Time On Prevention

Not Paperwork

Watch our overview video to see how your organization can benefit from Certainty.

Watch Video